Smart bridge implementation: Structural health monitoring in Oslavany

TwinBridge has provided us with highly detailed insights into the bridge’s structural behavior – information we did not have before. The system delivers unique data not only on deformations and deflections, but also on stress levels in key load-bearing elements and a comprehensive assessment of the bridge’s reliability and safety. Thanks to this unique data, we are now able to plan maintenance more effectively and proactively. We also appreciate the quick installation without the need for any structural intervention.

CLIENT

- Správa a údržba silnic Jihomoravského kraje

CURRENT STATE

- Road integral bridge with prestressed concrete abutments and a variable thickness deck

- During the inspection, a deflection in the bridge deck was observed, likely caused by formwork settlement during concrete casting

- The structure showed no visible damage

- No continuous deformation monitoring system was installed

EXPECTATIONS

- Obtain accurate data on real bridge deflections during normal operation

- Monitor structural deformation over the long term

- Minimize intervention in the structure during sensor installation

- Ensure reliable year-round continuous measurements

- Gain unique data on stress, reliability, and load-bearing capacity using AI analytics

We deployed a measurement system using modern Fiber Bragg Grating (FBG) technology. The structure was fitted with stainless steel mounting plates to attach the sensors. Two longitudinal fiber optic sensors were installed along the bridge length, with segmented measurement zones arranged in pairs at precisely defined intervals. These sensors track bridge deformations with microstrain-level accuracy, enabling detailed analysis of relative deformation and deflection.

To account for varying climate conditions, we recommend continuing the monitoring over the upcoming period.

Key outcomes

- Detailed and continuous data on deformation, stress, and structural reliability during real operation.

- Long-term monitoring of structural behavior.

- Sensor installation without intervention into the bridge structure.

- Real-time data on stress, reliability, and load-bearing capacity using artificial intelligence and machine learning.

- More effective maintenance planning and extended bridge lifespan.

Interested in TwinBridge?

Get your tailored offer.

Achieved results

Using data from the fiber optic sensors, we derived the bridge deflection curve mathematically. This validated the system’s functionality and ability to capture the structure’s response.

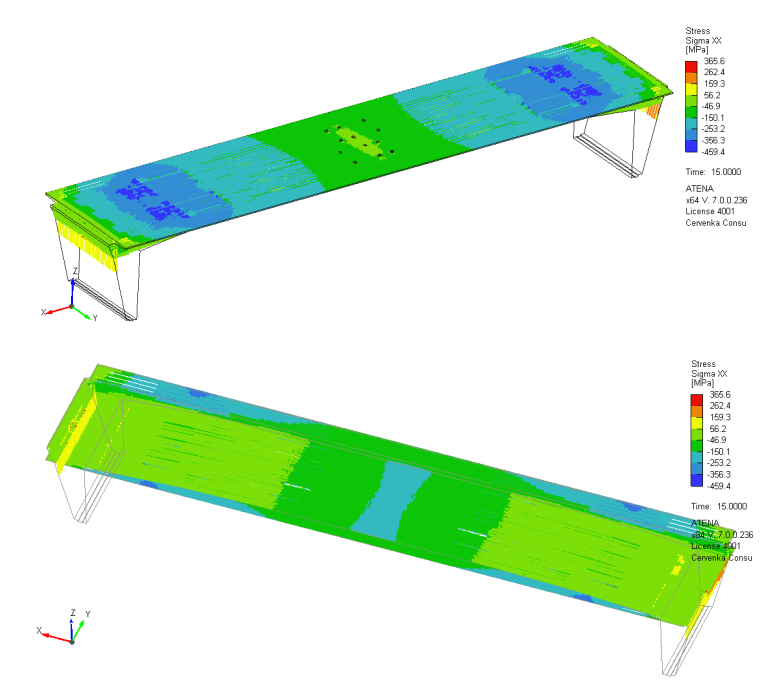

A numerical model of the bridge was then created and integrated with the measured data. This enabled us to capture the real structural behavior more accurately and better understand its mechanical response under various operational scenarios.

Advanced nonlinear simulations allowed us to validate the structural behavior, assess load limits, and simulate the bridge’s performance up to its ultimate capacity in a virtual stress test. AI and machine learning were used to translate the monitored data into engineering values, enabling tracking of reinforcement stress, prestressing cable force, reliability, and maximum load-bearing capacity.

The results serve as a foundation for predictive maintenance, enabling more accurate planning, cost reduction, and increased safety.

Note: The results were achieved as part of the project “Digital Twin for Enhancing the Reliability and Durability of Concrete Bridges,” funded with state support from the Technology Agency of the Czech Republic and the Ministry of Transport under the TRANSPORT 2020+ Program.

Project partners

Inquire about our monitoring solution

Don’t compromise on safety—contact us today to discuss how we can support your project with our cutting-edge monitoring technology.