Why TwinBridge

TwinBridge is a powerful tool designed to assess the reliability and sustainability of bridges and other transport structures. By leveraging cutting-edge technology, it creates a digital twin of a structure, providing real-time insights into its future behavior. This allows users to monitor structural health and overall condition, predict future behavior, and identify potential issues. As a result, TwinBridge helps optimize maintenance and decision-making, making structures safer, more reliable, and more sustainable over time.

A digital solution for

structural health monitoring

Precise real-time measurement

TwinBridge enables continuous monitoring of bridge loads during operation, providing immediate insights into their condition. This allows for quick identification of changes and prevention of critical situations that could compromise the safety and stability of the structure.

Installation without structural intervention

Our sensors are attached to the bridge structure using a special mounting adhesive, eliminating the need for drilling or other interventions. Installation is fast, and gentle, and does not require complex assembly work, minimizing the impact on the bridge’s operation.

Detailed engineering data for structural management

TwinBridge provides real-time analysis of key parameters of the bridge structure, including load, stress on individual components, and overall reliability. Accurate data allows for better maintenance planning, optimized operation, and extended bridge lifespan.

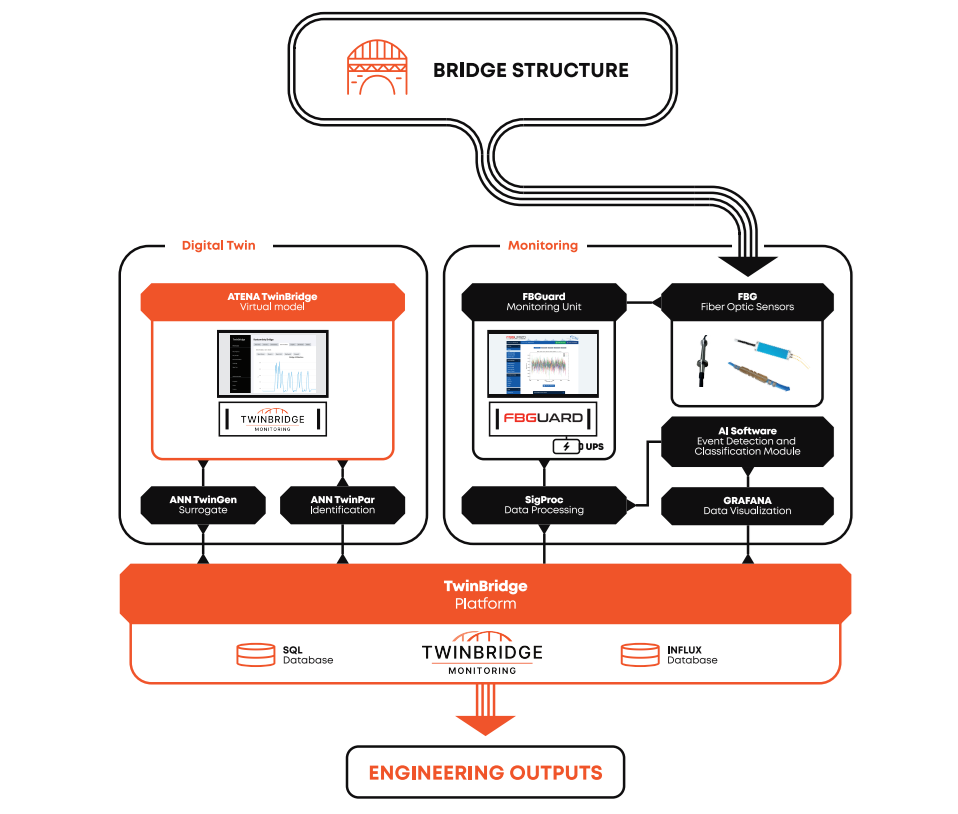

How does TwinBridge work?

I.

Digital twin creation

Advanced modeling creates an accurate virtual replica of the bridge, reflecting its real-world behavior.

II.

Real-time data collection

Optical sensors continuously monitor the bridge and instantly transmit data to the digital twin.

III.

Learning and predicting

Data analysis leverages artificial intelligence to uncover trends and predict risks, enabling timely maintenance.

Key engineering parameters

TwinBridge monitors critical parameters affecting bridge safety and longevity:

Stress and strain

Detecting the first signs of structural overload.

Vibrations and dynamic response

Identification of resonances that may lead to structural degradation.

Temperature and humidity

Recognition of conditions that contribute to material deterioration.

Tilt and displacement

Detection of dangerous structural movements.

Dynamic load

Monitoring the bridge’s response to traffic loads.

Corrosion

Detection of material changes that threaten load-bearing elements.

Certifications and standards

Our technology meets the highest industry standards:

ISO 9001

International standard for quality management systems.

ČKAIT

Static and Dynamic Analysis of Structures.

Compatibility

Integration capability with existing SHM systems.